SENSORS - ECA SENSORS - FLEXIBLE ECA SENSORS

The made-to-measure Eddy Current Array sensors that we manufacture respond to specific quality control procedures which are adapted to the shape of the parts to be controlled and can be placed with a specific tool in order to get quick and precise quality control results.

Our sensors can be connected to all Eddy Current Array machines on the market.

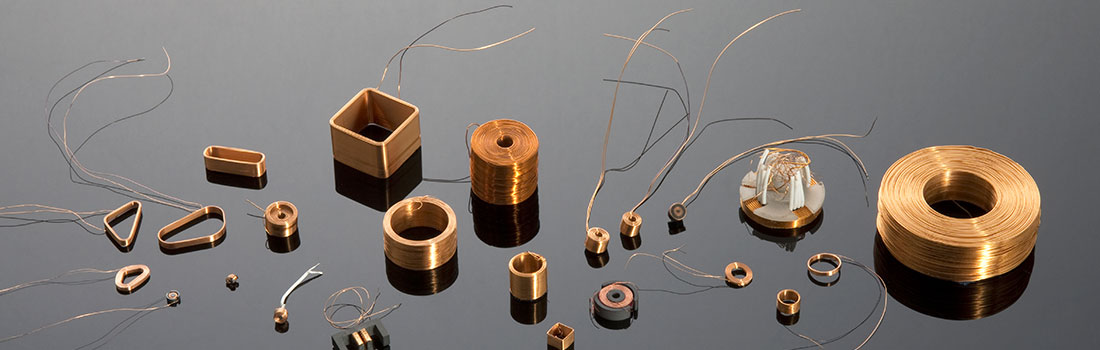

Classic sensors

The classic sensors are available in a large range of diameters, frequencies, and connector systems.

The following sensors are considered as 'classical':

- Standard surface sensors (with 1 to 4 active elements). There are several types of sensors depending on the required functions: absolute compensated, differential, emission-reception, and differential reception. For example, pencil shaped surface sensors with functions to detect and reveal surface or sub-surface fissures.

- Rotational sensors for scanning with a fixed or expandable diameter. We offer a wide range of expandable or fixed diameter rotational sensors to control the bore within a cylinder or metal grinded parts. All of our sensors can be adapted directly to all directional scanners or with an adaptor on all standard rotational scanners on the market.

ECA sensors

The ECA (Eddy Current Array) sensors are multi-element sensors with between 4 to more than 128 active elements.

The multi-element Eddy Current Array technology offers the possibility of electronically commanding and reading several Eddy Current Array sensors side-by-side in a single sensor. The collection of data is made possible thanks to multiplexing which avoids mutual induction between the coils.

The inspection time is reduced, up to 10 times faster than a classical inspection, and up to 15 times faster than a dye-penetrant inspection with increased probabilities of fault detection. The position of the sensor is less crucial than it is with pencil shaped or sliding sensors, and the time saved is considerable with a reduced risk of errors due to the simplified inspection procedure. Visualisation of the results can be viewed by mapping of the controlled areas (C-Scan), and furthermore, the traceability is guaranteed as the data is saved and archived.

Depending on the models, the systems work depending on the following functions: absolute, emission-reception, and emission-multiple-reception.

It is an innovative solution for detection of surface or sub-surface fissures to detect corrosion and/or welding points etc...

Multi-element technology is often linked to Eddy Current Array systems enabling intuitive imaging and easy reading.

Flexible ECA Sensors

The new technology for ECA (Eddy Current Array) flexible sensors integrates coils in a flexible film which provides the following advantages:

- Wider adaptability to surfaces with different shapes

- Greater flexibility on smooth or curved surfaces (complex geometry or other)

- Real-time measurements, readings, and results

There are two types of flexible sensors:

- ECA flexible sensors engraved on film which enables having a large number of active elements with a lower cost for manufacturing and cabling than with classic coils. This type of sensor enables wider flexibility and adapting for controlling complex or evolving surfaces.

- ?ECA mixed flexible sensors: classical coils integrated into a flexible matrix and a wider range and frequency for use, in particular with low frequencies in relation to engraved sensors.

A wider range of cover for a single sensor with high resolution.

This technology can be used in several industries to control surfaces and in particular welding points, the interior of tubes or pipes, turbines, fluorescent tubes etc...